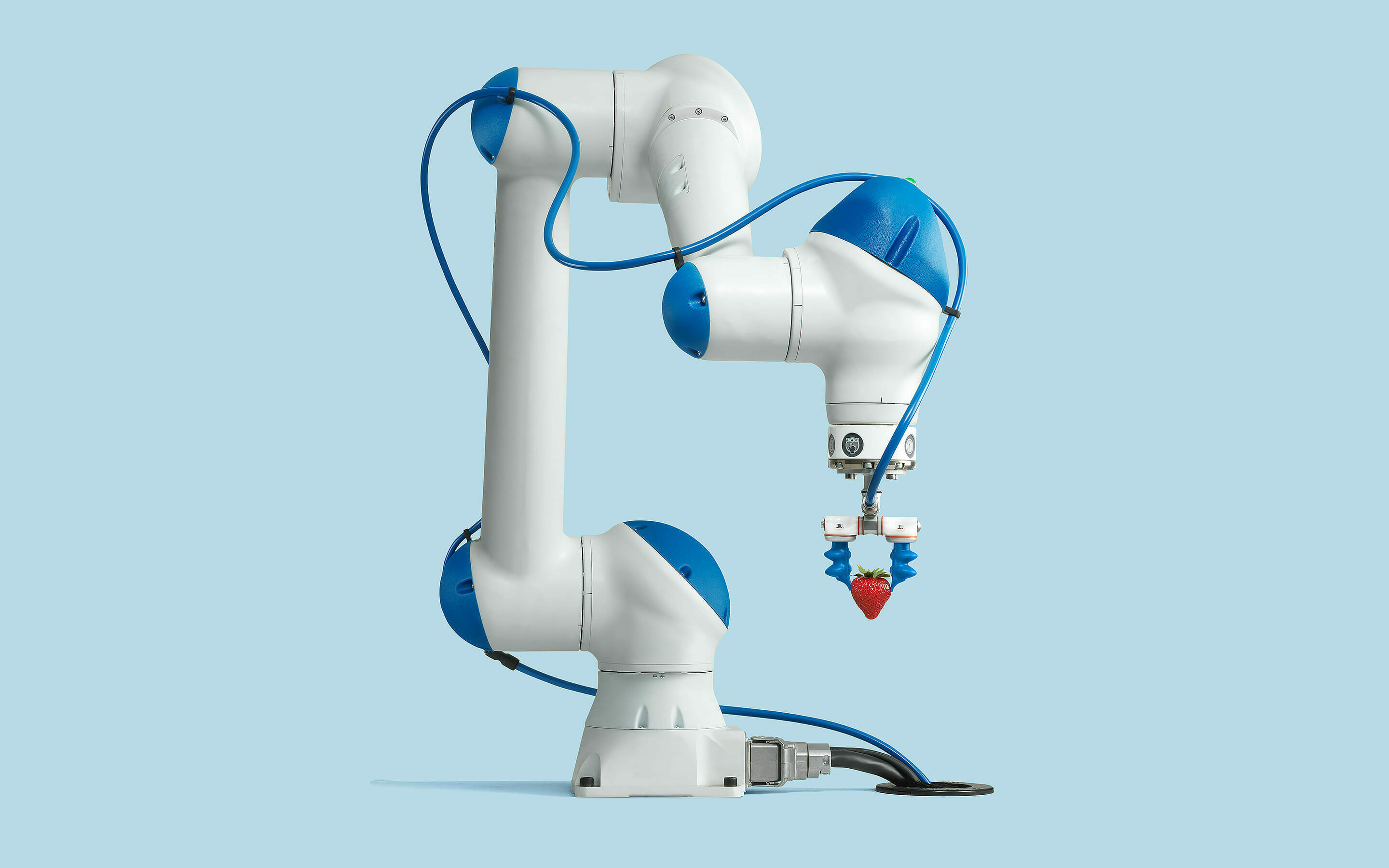

See how Soft Robotics is helping to reduce food waste.

Carl Vause, CEO, Soft Robotics

Carl Vause, CEO, Soft Robotics

Up Next:

Reshape the surface of the planet

Reshape the surface of the planet